Letterpress studio

Where traditional printing techniques meet contemporary design.

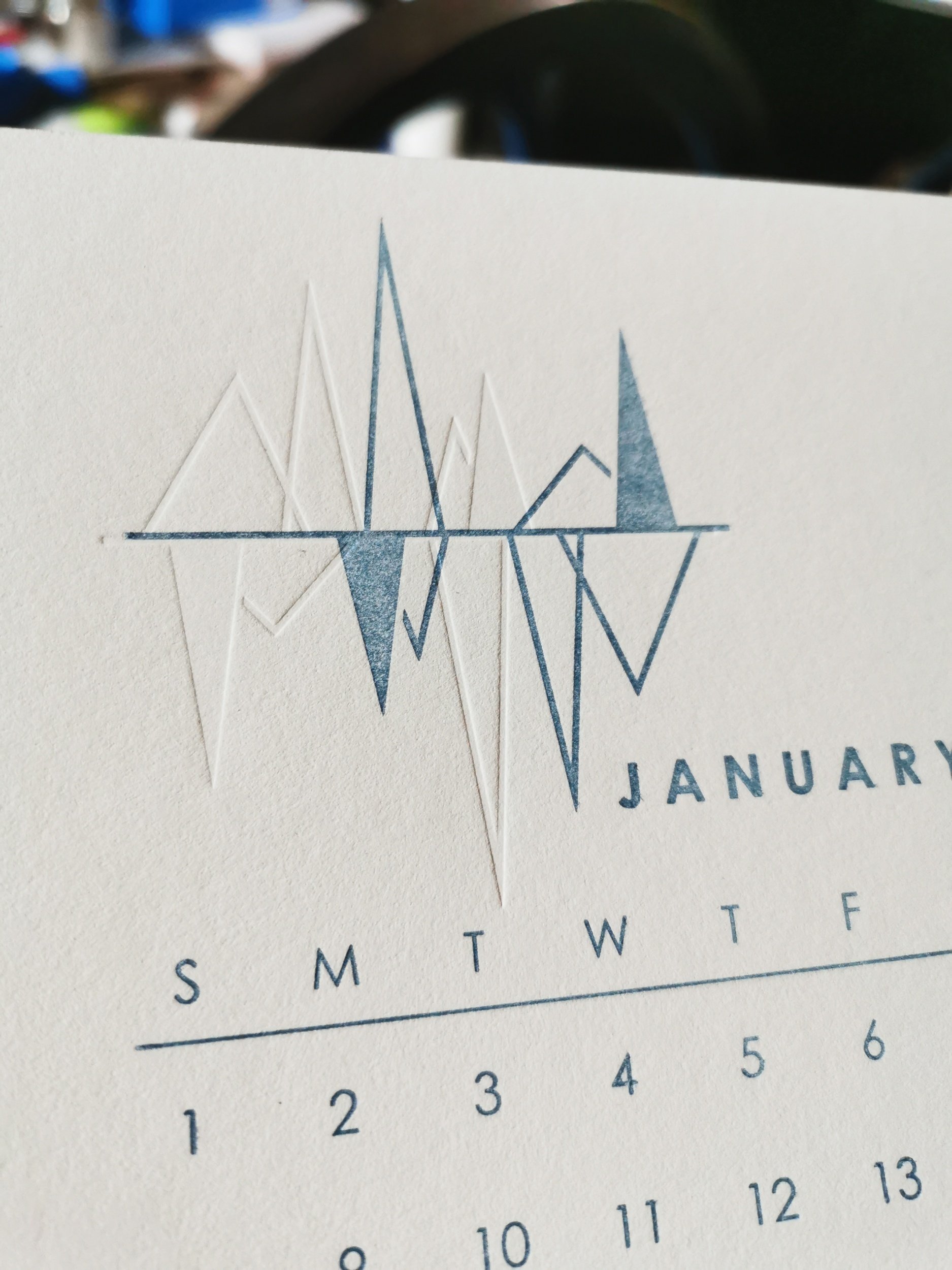

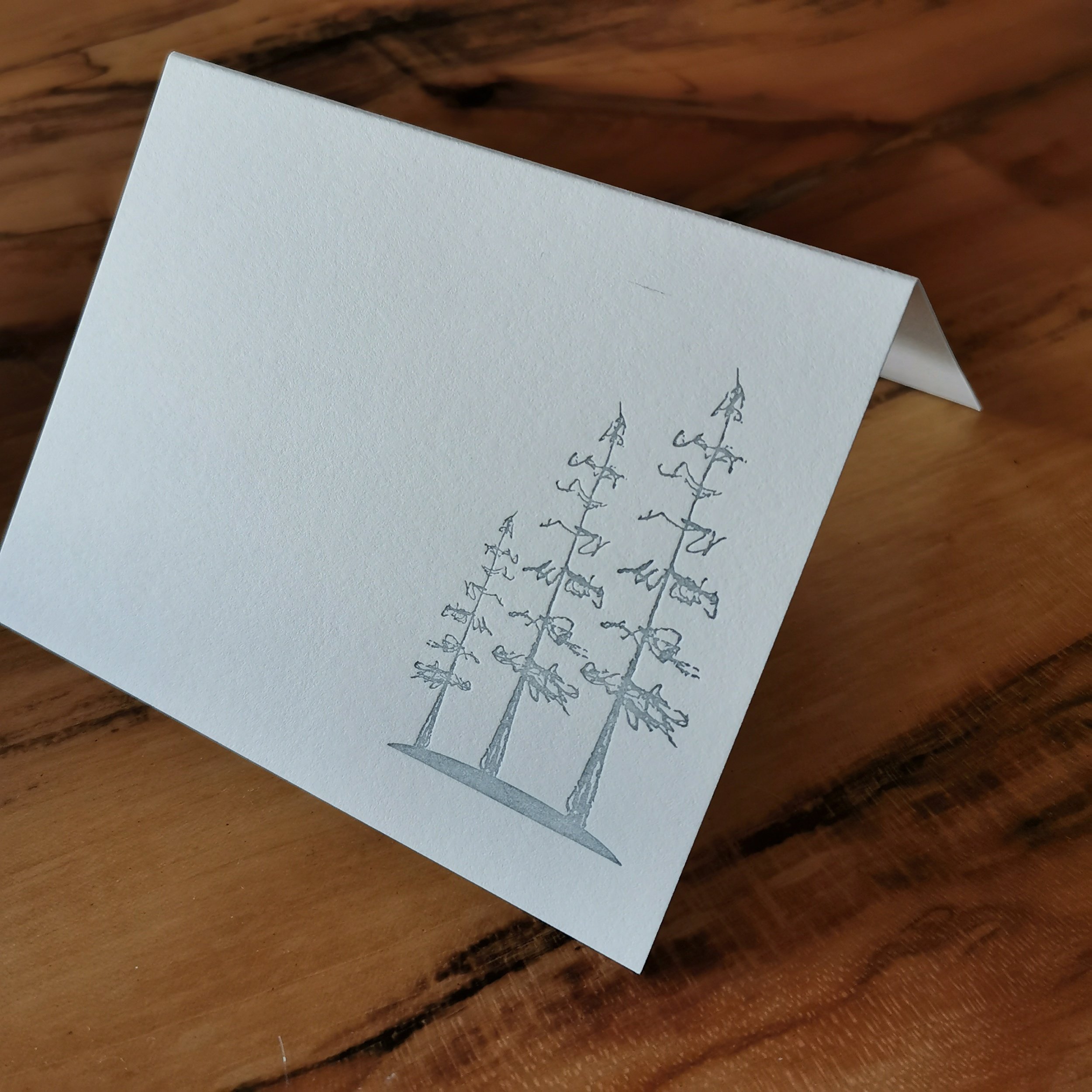

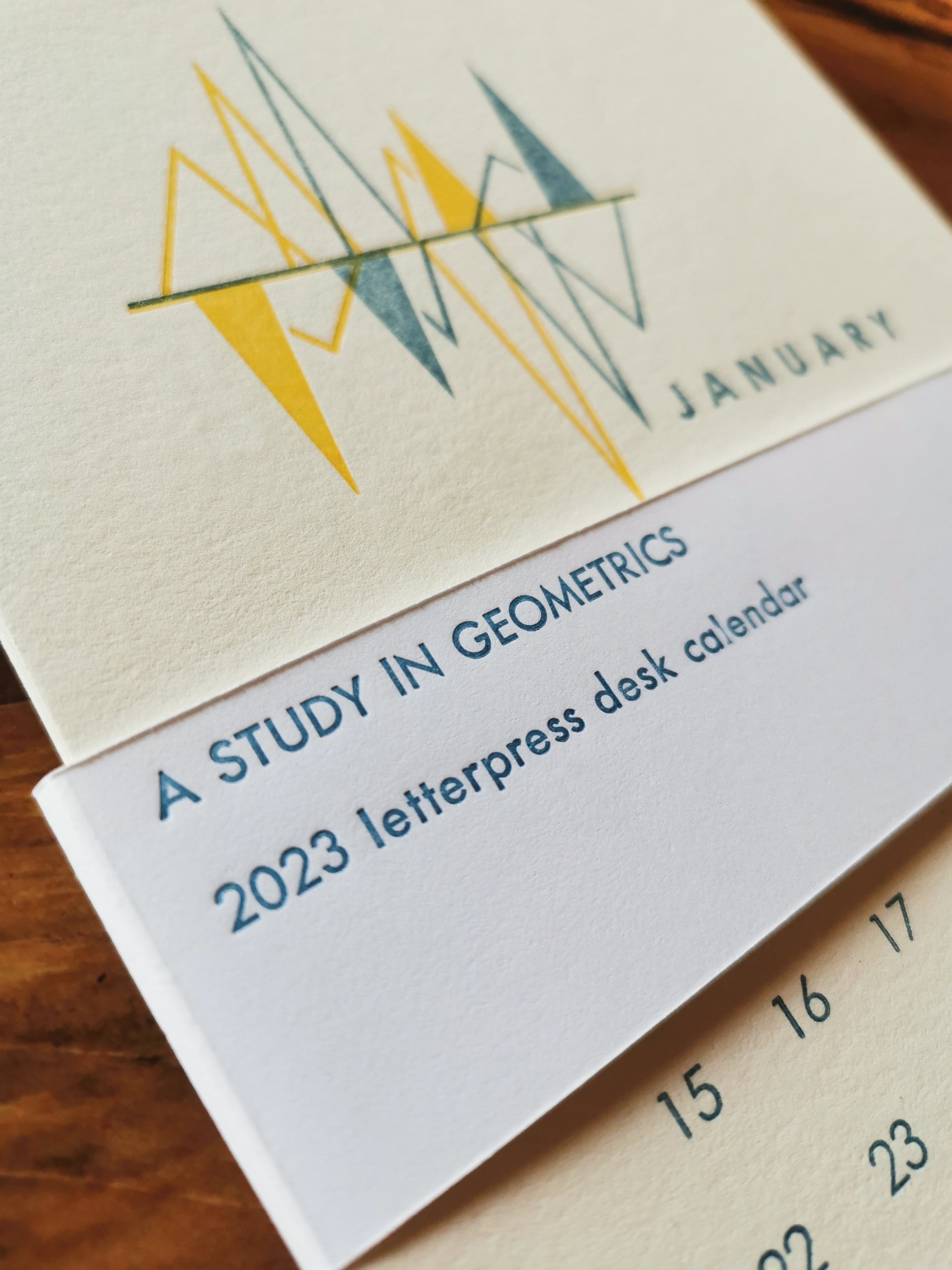

We specialize in creating beautiful and tactile printed materials using the centuries-old craft of letterpress printing combined with a modern approach. Each piece is carefully handfed on an 1890 Gordon Platen Press that is powered using a foot treadle. Due to the nature of printing, every press creates a completely unique print with slight imperfections, making each greeting card, invite, gift or business card a one of a kind work of art.

By mixing traditional printing methods of typesetting wood or metal individual type with more modern hand carved linoleum and photopolymer plates, I create beautiful and distinct products.

Interested in your own

letterpress project?

I would love to work with you! Get in touch to get started on your business cards, invitations, postcards and more.

Letterpress Process

Every part of the process is completed by hand form the ink mixing to type setting through to hand feeding the paper. Here is a brief run down of the process.

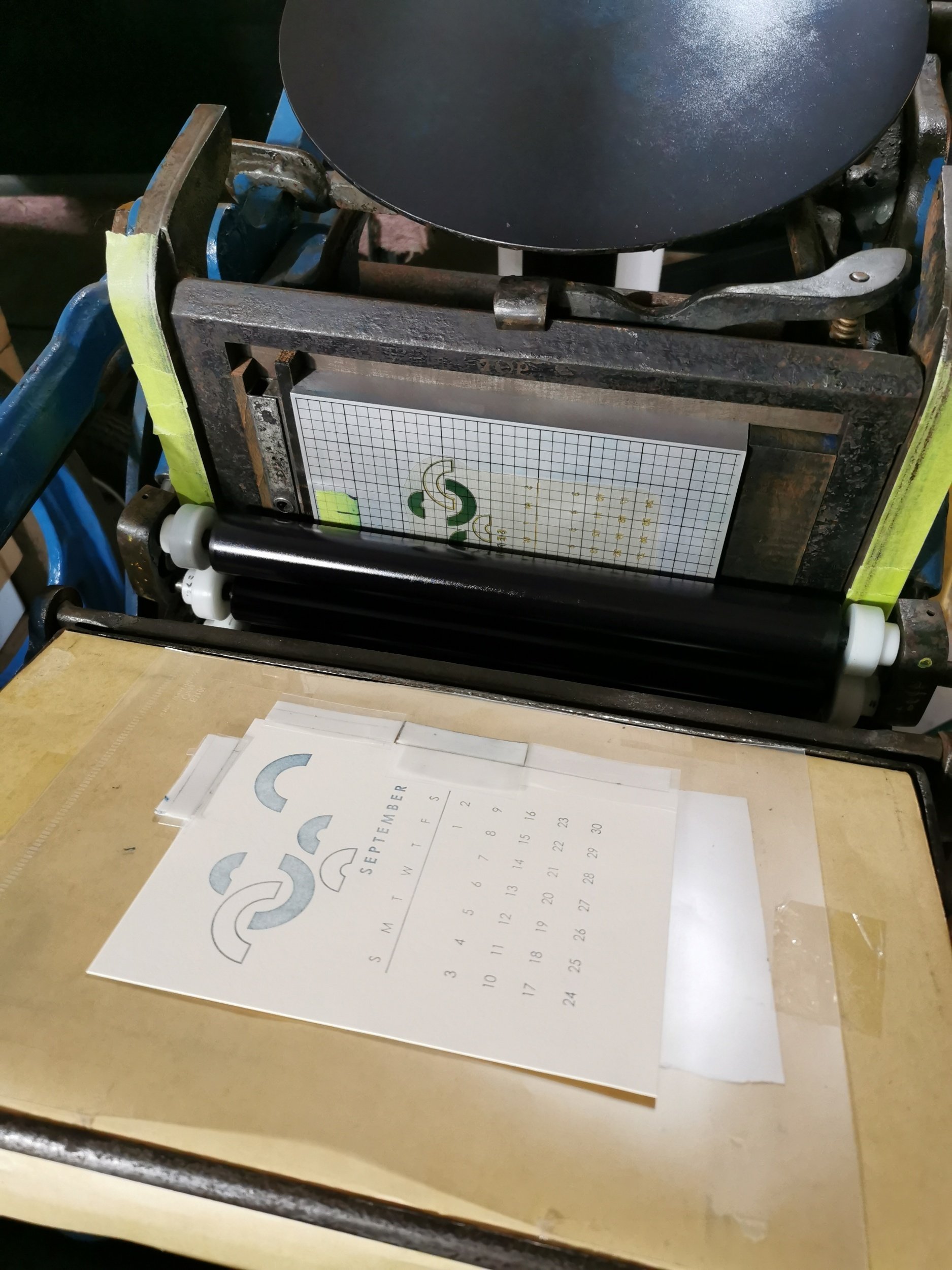

Prepare the printing plate or typeset your text: You can create your design digitally and have it printed on a polymer plate or you can typeset your project with individual lead or metal letters. Make sure the plate or text is properly positioned and locked up in the chase.

Mix the Ink: Measure out each ink colour and mix by hand to achieve your desired colour by following the proper formula.

Ink the press: Apply ink to the ink disc on your press, then use a roller to spread the ink evenly across the disc.

Load the paper: Determine where the paper needs to sit so that it makes a straight, clean impression in the correct spot.

Print: Start hand feeding the paper on to the platen and run the machine using the foot treadle. The rollers will bring the ink down over the chase which holds the plate or text. As the press closes, the raised plate will push into the paper and make an inked impression onto the paper. Remove the finished paper and repeat until done.

Clean up: Remove the printing plate from the press and clean. Remove any excess ink from the press and rollers, and clean the ink disc and ink rollers with solvent.

This process will have to be done for each colour of the artwork making it a lovely slowcraft in the world of art.